General rules for the selection of contact wheels can only be created to a very limited extend, due to the fact that the workpiece itself is the main factor. On the other hand the influence of the contact wheel is considerable and at least as big as that of the grinding belt. Durability and complete use of the grinding belt are depending on the selection of the suitable contact wheel as well.

Decades of experience in the production and supply of contact wheels enable us to give some information which may be used as a guidline:

The contact wheels with rubber- or moulded cushion (ELAX® GO … or ELAX® V …) may be used for water- or oil-based as well as for dry grinding processes. Their grade fo hardness, a main factor for the realisation of the required result, is measured in “Shore“. Besides that some common descriptions are available, such as “extra soft“ = abt. 30 Shore, “soft“ = abt. 40 Shore, “medium“ = abt. 60 Shore, “hard“ = abt. 80 Shores and “extra hard“ = abt. 90 Shore.

Contact wheels with textile cushions may only be used in the dry grinding process.

The correct selection of the cushion’s grooving is of major importance, too.

A large and wide groove works aggressively, therefore the use of more coarse grinding belts is logic. Contact wheels with smooth cushion are better for finer grinding belts. The grooving called “R“ is a standard grooving for universal grinding processes, whilst the one called “L“ helps to realise a more fine, even grinding. Besides these two some other kinds of grooving are available which we may recommend on request.

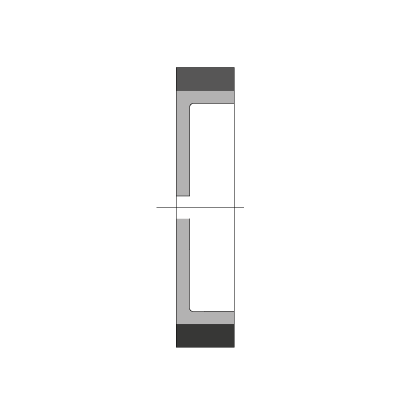

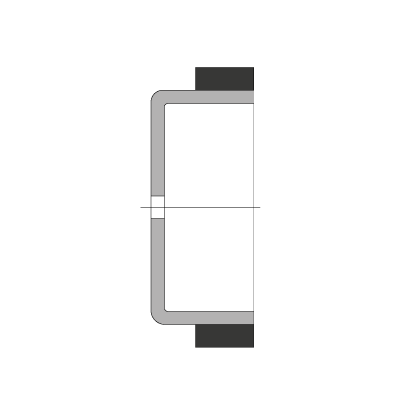

According to the desired use of the contact wheel a profiled cushion may be necessary. The various profiles being available are stated below and bear letters which must be part of your order.

The Version of the contact wheel’s hub may be different, depending on the machinery required. Some common shapes are stated below, too, and even their description must be part of your order.

Last but not least the speed of the contact wheel is of major influence for the result.

| We recommend the following speed | |

|---|---|

| 200 mm | 1500-3500 rpm |

| 250 mm | 1200-2800 rpm |

| 300 mm | 1000-2300 rpm |

| 350 mm | 900-2000 rpm |

| 400 mm | 750-1750 rpm |

| 450 mm | 700-1550 rpm |

These data are corresponding to a speed of 16-36 m/sec.

| contents of order | |

|---|---|

| Type of contact wheel | e.g. ELAX® GOR |

| Hardness of cushion | e.g. medium |

| Grooving | e.g. “L“ |

| Dimension | e.g. 250x50x56 mm |

As a standard, our contact wheels have a hole of 56 mm. Should you require a different diameter, please state this in your order. Contact wheels being stock types can be reduced from 56 mm down to any diameter required.

Should the information of this catalogue not be sufficiant for you and should you require our specific advice, do not hesitate to send a sampleworkpiece. Our abrasive experts in our laboratory are available to find the right selection for you. Our advice will be accompained by a test-record for your reference. In case of orders to follow this service it is free of charge for you.